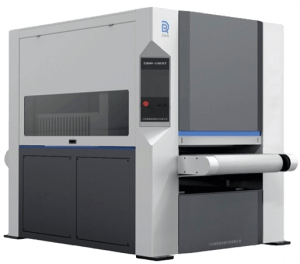

JC1300

●Pass-through processing, complete deburring and chamfering in one feed;

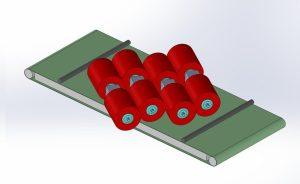

●Four groups of flexible grinding roller grinding mechanism;

●Standard vacuum conveying platform;

●Deburring and chamfering of workpieces with film; .

●It can handle even R angle not less than 1mm, which is suitable for customers with high R angle requirements:

●Imported consumables are used, with long service life and good consistency.

FUNCTION

JC1300 uses a flexible grinding roller grinding mechanism to evenly clean and polish the edge of the workpiece and around the hole, so as to obtain a smooth surface and soft corners. For deburring laser cut, waterjet cut, stamped and cut workpieces. Preliminary removal of large burrs and surface brushing in one process. Use a set of roller brushes for metal chamfering, surface drawing, and special abrasive belts to remove scale. The processing cost is low, the energy consumption is very low, the use is simplified to the greatest extent, and the machining is optimized. While not affecting the size of the workpiece, the perfect surface effect can be obtained, which provides a safe and reliable guarantee for the subsequent assembly and spraying of sheet metal workpieces.

CHARACTERS

- Dry operation.

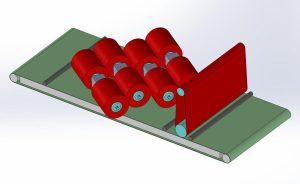

- Wide abrasive belt head for sanding out the burrs or surface finishing.

- Planetary type abrasive barrel station for further edge rounding, 6 abrasive barrels, and planetary rotation.

- Vacuum conveyor table to accommodate small parts, smallest parts available 50x50mm.

- Planetary abrasive barrel station will only focus on the edges and contours of the parts, minimum effect on the whole surface.

- Capable of processing minor formed /profiled parts.

- Long life span of consumables.

- Straight forward and user-friendly operation.

- Auxiliary LED lighting inside machine.

- Dust collection hood is installed inside the machine.

STRUCTURE

Model: JC1300

With only 8 planetary abrasive polishing barrels for light burr removal and edge rounding.

Model: JC1300-BG

With wide sanding belt for heavy burr removal and 8 planetary abrasive polishing barrels for secondary burr removal and edge rounding.

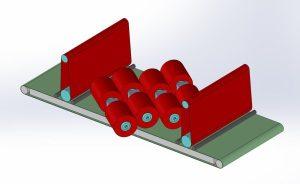

Model: JC1300-GBG

With wide sanding belt for heavy burr removal and 8 planetary abrasive polishing barrels for secondary burr removal and edge rounding. last wide sand belt is for straight line finishing.

PARAMETERS

| Working width | ≤1300mm | Brush roller size | φ300mm×300mm |

| Min. working size | 50x50mm | Dust collector | 4000m³/h |

| Working thickness | 0.3~80mm | Total power | 40KW |

| Feed speed | 0.5~5m/min(adjustable) | Working height | 930±30mm |

| Revolution speed | 2~17r/min(adjustable) | Profile dimension | 2650×2400×2200mm |

| Head speed | 1000r/min | Weight | 5T |

| Number of planetary shafts | 1 | Abrasive material | Belt + brush roller |

| Brush head | 8 | Belt size | 1910MM x 1300MM |

MATERIAL

- Carbon steel, stainless steel, Aluminium, Copper, graphite, etc.

- Parts with protective vinyl film (machine will not damage the film, therefore protect the

surface underneath). - Working thickness range from 0.5mm- 100mm.

- Carbon steel parts that require large radius on the edges

VIDEO