JC400

- Strong vacuum adsorption, through processing, high processing efficiency.

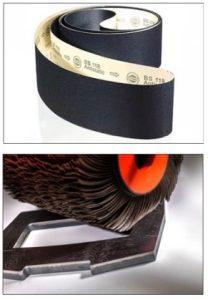

- Combination of narrow abrasive belt and universal roller brush, deburring and rounding.

- Compact design, does not take up space.

- Equipped with a powerful vacuum cleaner, energy saving and environmental protection

FUNCTION

JC400-ZP is an economical deburring machine developed for small parts. It can deal with the deburring of various metal laser cutting small parts and stamping small parts. The R corner is rounded and blunt.

CHARACTERS

- Dry operation.

- Narrow abrasive belt head for sanding out the burrs or surface finishing.

- Vacuum conveyor table to accommodate small parts, smallest parts available 50x50mm.

- Capable of processing minor formed /profiled parts.

- Long life span of consumables.

- Straight forward and user-friendly operation.

- Auxiliary LED lighting inside machine.

- Dust collection hood is installed inside the machine.

PARAMETERS

| working width | ≤400mm | Total power | 12.5KW |

| Min. working size | 50x50mm | Working height | 890mm |

| Working thickness | 0.3~80mm | Profile dimension | 2420×1140×1920mm |

| Feed speed | 1~6m/min(adjustable) | weight | 1100kgs |

| Conveyer table | vacuum | Abrasive material | Belt + brush roller |

| Head speed | 1440r/min | Belt size | 1380MM✖80MM |

| Dust collector | 1000-1875m³/h |

VIDEO